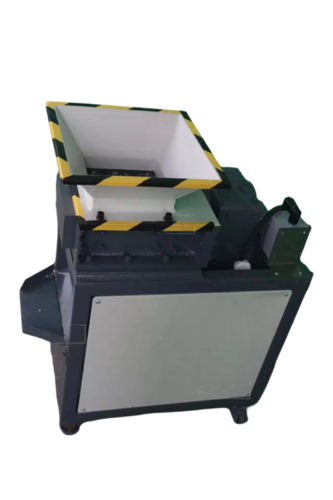

Polythene Waste Shredder for Recycling industry

Polythene Waste Shredder for Recycling industry Specification

- Thickness

- Up to 10 mm

- Control System

- PLC Controlled

- Capacity

- Up to 500 Kg/Hr

- Size

- Customizable

- Color

- Green & Blue

- Noise Level

- Low (<75 dB)

- Voltage

- 380 V

- Motor Power

- 10 HP

- Processing Type

- Shredding

- Application

- Polythene Waste Recycling

- Sheet Capacity

- Multiple Sheets

- Material

- Mild Steel

- Weight

- Approx. 700 Kg

- Automatic Grade

- Automatic

- Frequency

- 50 Hz

Polythene Waste Shredder for Recycling industry Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Mumbai

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Wooden Box

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Certifications

- CE

About Polythene Waste Shredder for Recycling industry

The recycling industry plays a pivotal role. One company that stands at the forefront of this revolution is SHREDALL, with its innovative Polythene Waste Shredder. This high-performance shredder is designed to handle plastic waste efficiently, making it a game-changer for the recycling industry.

The SHREDALL Polythene Waste Shredder is engineered with precision and innovation to meet the demands of the recycling industry. Its state-of-the-art design ensures optimal performance, enabling facilities to process large volumes of polythene waste with remarkable efficiency. The shredders robust construction guarantees durability, making it a reliable asset for the long haul.

The Working of Polythene Waste Shredder

Certainly, here's how a double shaft shredder from SHREDALL operates:

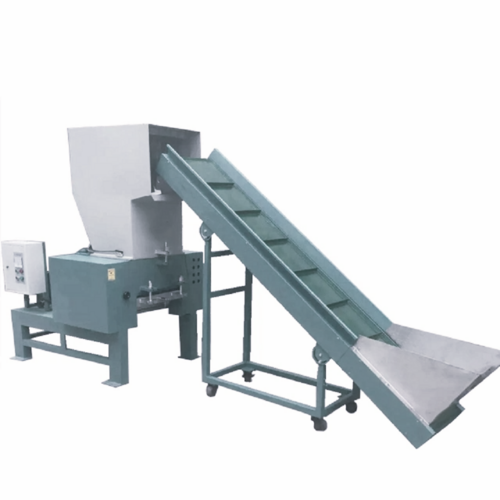

Feeding System: Polythene waste is efficiently fed into the SHREDALL shredder.

Shredding Chamber: Within the shredding chamber, the waste encounters the rotating cutting blades.

Double Shaft Shredding: SHREDALL's shredder features two cutter shafts with staggered blades, effectively shearing the material into small pieces during rotation.

Discharge System: The shredded plastic is collected for further processing or recycling.

This streamlined process enables the recycling industry to handle large quantities of polythene waste efficiently.

Key Features

The SHREDALL Polythene Waste Shredder offers cutting-edge dual-shaft design for efficient polythene waste shredding. With PCB certification, it meets environmental standards for responsible e-waste disposal. Equipped with efficient shredding technology, it securely processes various digital devices. Its versatility and environmental impact make it an ideal solution for managing e-waste sustainably.

Shredding Material

The SHREDALL Polythene Waste Shredder is specifically designed to shred polythene waste efficiently. Its cutting-edge dual-shaft design ensures effective shredding of various types of plastics, from rigid to flexible, making it a versatile solution for recycling facilities. Whether it's polythene bags, packaging materials, or other forms of polythene waste, the SHREDALL shredder can handle them with ease, contributing to efficient waste management and recycling efforts.

Shredding Machine Type

The SHREDALL Polythene Waste Shredder is classified as a dual-shaft shredder. This type of shredder utilizes two cutter shafts equipped with staggered blades to efficiently shred polythene waste.

Usage/Application

The SHREDALL Polythene Waste Shredder is versatile, finding applications in recycling facilities, manufacturing plants, retail centers, municipalities, and environmental cleanup projects. It efficiently shreds polythene waste, including packaging materials and defective products, promoting sustainable waste management practices across various industries.

Capacity

With a shredder from 100 kgs/hr to 1000 kgs/hr, the machine is available for small, medium to large-scale operations.

Automation Grade

The Shredder Machine is fully automatic, which makes it easy to operate.

Motor Power

The machine runs on a 3 Phase power supply, ensuring efficient and reliable performance.

Country of Origin

Proudly made in India, SHREDALL industrial Shredder Machine is a testament to the country's manufacturing prowess.

High Performance and Easy Installation

The SHREDALL Polythene Waste Shredder combines high performance with easy installation. Its cutting-edge design ensures efficient shredding of polythene waste, while its user-friendly setup makes installation straightforward, Enjoy hassle-free setup with free installation services provided by SHREDALL. With SHREDALL, businesses can achieve optimal waste management without compromising on performance or convenience.

Product Description

Introducing the SHREDALL Polythene Waste Shredder a cutting-edge solution for efficient waste management. With its dual-shaft design, it efficiently shreds polythene waste, promoting sustainability across various sectors. High performance and environmentally friendly, it reduces waste volume effectively while minimizing the carbon footprint. Upgrade your waste management system with SHREDALL for efficient, eco-friendly, and hassle-free waste disposal.

Contact Us

We are here to assist you. Feel free to Contact Us Call / WhatsApp / Email :

-

Email: info@shredall.in

-

+91 9820020754

Conclusion

SHREDALL Polythene Waste Shredder is a powerful and efficient machine designed for the recycling industry. Its double-shaft design allows it to handle a variety of materials, including polythene, mixed materials, metals, and e-waste. The shredders high performance, user-friendly interface, and comprehensive safety features make it an excellent choice for recycling facilities. By investing in this shredder, companies can contribute to reducing landfill waste and promoting a more sustainable future. Always remember to check the manufacturers instructions for the specific model youre interested in. Its a great way to manage polythene waste in an eco-friendly manner, Spend Less Benefits More.

Efficient Shredding for Polythene Waste

Our shredder is engineered to handle multiple sheets of polythene waste efficiently, processing up to 500 Kg/Hr. The high-carbon steel blades and 1200 RPM rotation ensure effective shredding of even thick materials up to 10 mm. This machine is ideal for recycling centers and manufacturing units dealing with polythene waste in bulk.

Automatic and Safe Operation

The shredder's PLC-controlled automatic feeding mechanism enhances productivity while ensuring operator safety. Equipped with overload protection and emergency stop functions, it guarantees secure operation during continuous processing. Its mobility on wheels ensures flexible placement within any workspace.

Simple Maintenance and Customization

With easy access for cleaning and servicing, maintaining optimal performance is hassle-free. The shredder is available in customizable sizes and colors (green & blue) to match your facility's requirements. Installation and after-sales service support are available upon request anywhere in India.

FAQ's of Polythene Waste Shredder for Recycling industry:

Q: How does the automatic hopper feeding system improve the shredding process?

A: The automatic hopper feeding mechanism ensures a continuous and consistent flow of polythene waste into the shredder, reducing manual intervention and boosting overall processing efficiency. It also helps in maintaining operator safety by minimizing direct contact with moving parts.Q: What type of blades are used and how durable are they for polythene shredding?

A: The shredder is equipped with high carbon steel blades, which provide excellent durability and sharpness. This material is specifically chosen for its ability to withstand frequent heavy-duty shredding of thick polythene sheets, ensuring longevity and minimal blade maintenance.Q: When is routine maintenance recommended for optimal performance?

A: Routine maintenance should be conducted as per the manufacturer's guidelines, typically after every major shredding session or as needed based on the volume of material processed. The shredder allows easy access for cleaning and servicing, making maintenance quick and straightforward.Q: Where can this polythene shredder be installed, and are installation services provided?

A: This shredder is suitable for any industrial recycling facility or manufacturing unit in India. Installation services are available on request to help set up the equipment and integrate it with existing production lines.Q: What is the process for polythene shredding, and what is the typical output?

A: Polythene waste is loaded via the automatic hopper, shredded by high-speed rotating blades, and discharged through a conveyor or bin output system. The machine can process up to 500 Kg per hour of polythene material, depending on the input size and thickness.Q: How do the safety features work to protect users during operation?

A: The shredder includes overload protection to prevent damage from excessive material or resistance, as well as an emergency stop button to immediately halt operation if needed. These features greatly reduce the risk of injury or equipment failure.Q: What are the key benefits of using this polythene shredder for recycling operations?

A: Key benefits include high throughput, customizable size, low noise operation, enhanced safety features, and easy mobility. By efficiently reducing polythene waste volume, it helps recycling facilities streamline processes and increase output.

Price 300000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Shredder Category

Double shaft Plastic scrap crusher Machine

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Processing Type : Crushing & Shredding

Material : Mild Steel

Voltage : 380V

Plastic Bags Shredder Machine

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Processing Type : Single Shaft

Material : Hardened Metal

Voltage : 440 Volt (v)

Plastic Waste Shredding Machine

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Processing Type : Double Shaft

Material : Hardened Metal

Voltage : 440 Volt (v)

recycling plastic bottles Shredder Machine

Price 300000 INR / Piece

Minimum Order Quantity : 10 Pieces

Automatic Grade : Automatic

Processing Type : Double Shaft

Material : Hardened Metal

Voltage : 440 Volt (v)

GST : 27ABKCS4515J1Z1

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free